Greatly reduces vibration and noise during driving.

Greatly reduces vibration and noise during driving.  Improve driving comfort.

Improve driving comfort. Reduce the possibility of detachment.

Reduce the possibility of detachment. Improve the service life of the machine and reduce maintenance costs.

Improve the service life of the machine and reduce maintenance costs.

AVT TRACK

Taite's AVT tracks have high recognition in overseas markets, especially in Europe. AVT tracks adopt a unique diamond shaped iron tooth. The advantages are as follows:

TAITE

-

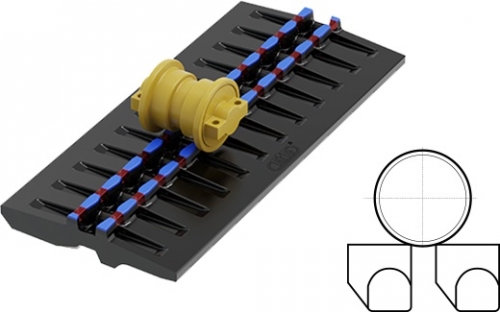

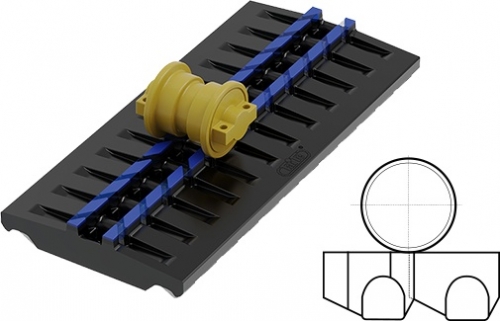

Traditional Track

There are gaps between the support surfaces formed by the iron teeth of traditional tracks, and the rollers experience significant vibrations when traveling on these support surfaces.

-

AVT Track

The unique diamond shaped iron tooth structure of the AVT track forms a continuous support surface for the rollers, achieving the effect of shock absorption.

Technical Parameter

| Track Size (WidthxPitch) | Inner Guide Width (A) | Outer Guide Width (B) | Inner Height (C) | Outer Height (D) | Track Thickness (H) | Section View | Gude Type | Traditional | AVT |

| 180x72 | 23 | 64 | 29 | 26.5 | 59 | Fig 1 | A/B | ■ | |

| 180x72K | 23 | 65.5 | 29 | 27 | 65 | Fig 2 | C | ■ | |

| 190x72 | 23 | 66 | 28.5 | 26 | 67 | Fig 1 | A/B | ■ | |

| 200x72 | 23 | 66 | 29 | 26 | 64 | Fig 1 | A/B | ■ | |

| 200x72K | 23 | 65.5 | 29 | 27 | 65 | Fig 2 | C | ■ | |

| 230x72 | 24 | 74 | 29 | 27 | 70 | Fig 1 | A/B | ■ | |

| 230x72K | 23 | 71 | 29 | 28 | 70 | Fig 2 | C | ■ | |

| 230x48 | 25 | 68.5 | 21.5 | 24 | 68 | Fig 3 | D | □ | ■ |

| 230x48K | 25 | 64 | 19 | 19.6 | 61 | Fig 4 | K | ■ | |

| 230x96 | 25 | 68 | 21.5 | 23 | 68 | Fig 3 | D | ■ | |

| 250x48.5Y | 27 | 65 | 20 | 18.5 | 74 | Fig 3 | K | ■ | |

| 250x52.5 | 30 | 79 | 23.5 | 22 | 75 | Fig 3 | D | ■ | |

| 250x72 | 23 | 78 | 30 | 27 | 71 | Fig 1 | A/B | ■ | |

| 250x72K | 23 | 71 | 29 | 28 | 70 | Fig 2 | C | ■ | |

| 265×72 | 23 | 78 | 30 | 26 | 72.5 | Fig 1 | A/B | ■ | |

| 300x52.5N | 29 | 80 | 24 | 20 | 74 | Fig 3 | D | □ | ■ |

| 300x52.5W | 39 | 92 | 23 | 21 | 76 | Fig 3 | D | □ | ■ |

| 300x53K | 31 | 85 | 24 | 21.5 | 76 | Fig 4 | K | ■ | |

| 300x55 | 28 | 82 | 24 | 25.5 | 83 | Fig 3 | D | ■ | |

| 300x109 | 36 | 93 | 25 | 27 | 87 | Fig 3 | D | ■ | |

| 320x52.5N | 29 | 80 | 24 | 19 | 74 | Fig 3 | D | ■ | |

| 350x52.5W | 39 | 92 | 23 | 21 | 76 | Fig 3 | D | ■ | |

| 350x54.5K | 40 | 93 | 23.5 | 21.5 | 85 | Fig 4 | K | ■ | |

| 400x72.5N | 36.5 | 95 | 26 | 24.5 | 90 | Fig 3 | E | □ | ■ |

| 400x72.5W | 49 | 106 | 24 | 22.5 | 89 | Fig 3 | D/E | □ | ■ |

| 400x72.5K | 47 | 107 | 23.5 | 22 | 87 | Fig 4 | K | ■ | |

| 450x71 | 40 | 112 | 30 | 25 | 100 | Fig 3 | D/E | □ | ■ |

| 450x76 | 49 | 118 | 28.5 | 30 | 106 | Fig 3 | D/E | □ | ■ |

| 450x81N | 42 | 110 | 29.5 | 28 | 100 | Fig 3 | D/E | □ | ■ |

| 450x81W | 53.5 | 136 | 29 | 33 | 106 | Fig 3 | D/E | □ | ■ |

| 450x81.5N | 42 | 109 | 30.5 | 27 | 97.5 | Fig 3 | D | □ | ■ |

| 450x83.5K | 41 | 110 | 23 | 26 | 105 | Fig 4 | K | ■ | |

| 500x92 | 61 | 152 | 31.5 | 34.5 | 129 | Fig 3 | D/E | ■ |

Instructions:

1. "□" indicates that there are corresponding traditional track types available for selection.

2. When a specification includes both traditional and AVT types, the parameter in the table refer to the AVT type (marked with "■")